Based on the research conducted, the answer to the question of What is an industrial pressure washer or waterjet can be summarized as follows: A pressure washer or car wash is a semi-industrial structure used for cleaning and removing pollution from various surfaces and objects. This device can play a significant role in environmental and community health.

Its application extends to improving the performance and lifespan of various structures. In essence, a pressure washer is a system that receives water from an external source and expels it with a higher flow and pressure. The fundamental operation of a pressure washer involves applying strong pressure to contaminated areas to break down and dissolve the molecular and chemical bonds of contaminants, ultimately delivering a clean environment.

Technical specifications of an industrial pressure washer:

During the cleaning process, a pressure washer enables access to blind spots and hard-to-reach areas, resulting in enhanced cleaning quality and speed. The pressure washers available in the market are generally categorized into two groups based on the applied pressure: high-pressure and ultra-high-pressure washers. The first type is suitable for cleaning tasks such as graffiti removal, rust removal, and cleaning uneven surfaces. On the other hand, industrial pressure washers with ultra-high pressure are effective in heavy-duty projects such as stripping surfaces, paint removal, and concrete demolition.

Types of Industrial Pressure Washers

It is clear that an industrial product can be classified based on various parameters. This rule also applies to industrial pressure washers. One of the main criteria for classifying pressure washers is whether the water is hot or cold. Therefore, the types of pressure washers include hot water pressure washers, cold water pressure washers, and home pressure washers.

Industrial Hot Water Pressure Washer

The hot water pressure washer is a fully industrial device. This machine contains a heater that increases the water temperature. This product itself includes three categories: diesel-powered, gasoline-powered, and electronic. Since hot water is used in this device, it has the capability to disinfect surfaces. Since the sudden entry of hot water can damage the pressure washer, the water in other structures heats separately.

Industrial Cold Water Pressure Washer

The cold water pressure washer essentially uses ordinary water without any temperature increase. In this pressure washer, water passes through the pump system and exits through the nozzle with increased pressure. This device has a lower cost compared to hot water pressure washers and can be used in semi-industrial activities such as woodworking.

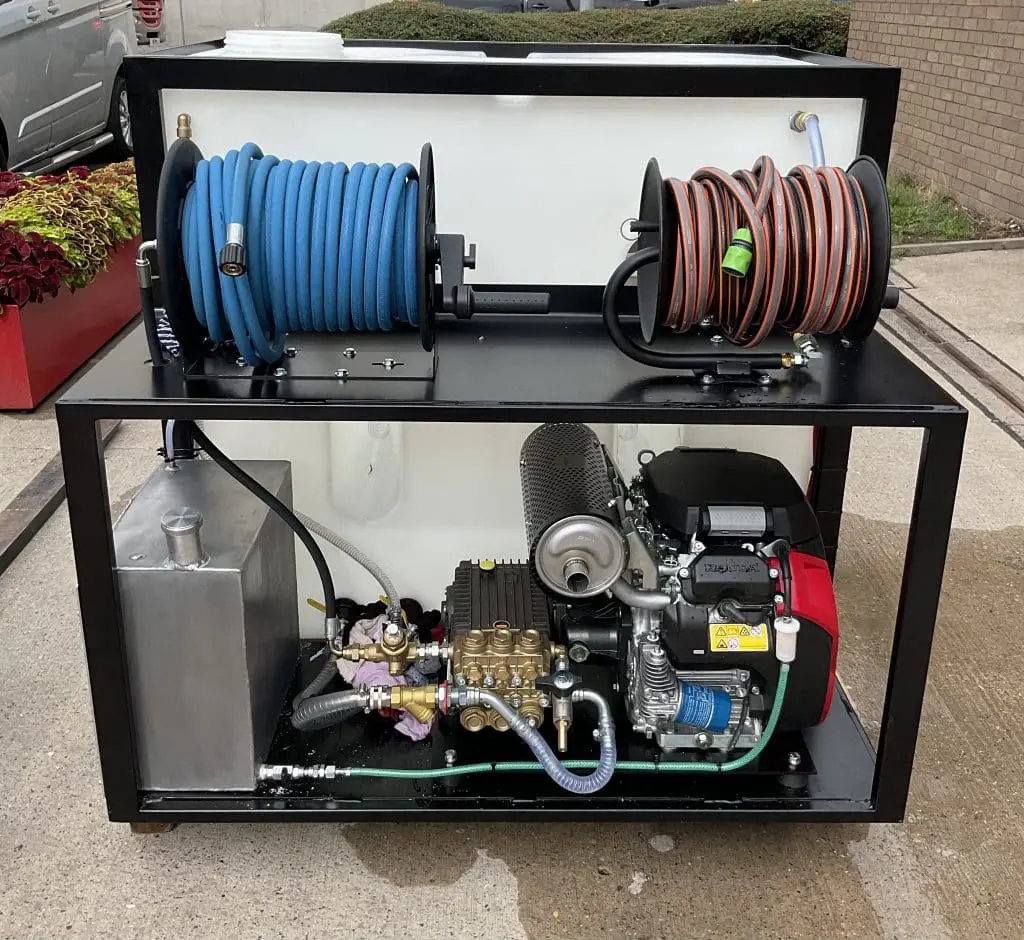

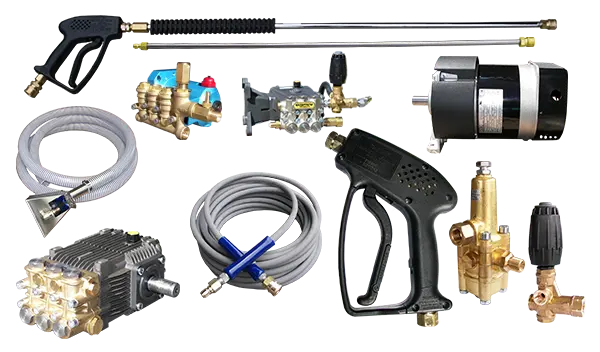

Components of Industrial Pressure Washers

It is evident that every industrial product is composed of various components, large and small, whose functionality is complemented by them. Consequently, if any of the pressure washer parts are absent, either internally or externally, the pressure washer cannot function properly and precisely. Although these components may vary in different types of pressure washers, the main components in this field are as follows:

Anti-vibration bases

Wheels

On/Off switch

Nozzle holders

Chassis

Couplings

Oil gauge

Pressure adjustment screw

Gun or lance

Rotating nozzle

Hose handle collector

High-pressure hose

Pressure washer handle

Applications of Industrial Pressure Washer

Cleaning barbecues, cleaning surfaces of commercial centers and parking lots, degreasing industrial equipment, stain removal, and car washing are among the important applications of industrial pressure washers. This device performs the cleaning process with high speed and precision, being able to access many blind spots. Using this device can guarantee the cleanliness of various surfaces. Additionally, by cleaning the pollutants from various structures, it increases their lifespan and improves their performance.

How Industrial Pressure Washers Work

To start the pressure washer, it is enough to connect the hose to it and by connecting the various components of the structure to each other, press the On/Off button. It is worth mentioning that some pressure washers in their structural design have an additional reservoir that eliminates the risk of pump damage and water flow fluctuations.

Advantages of Using Pressure Washers

This device requires a minimal amount of water and detergent for the washing process. Therefore, it can be considered an environmentally friendly product. Moreover, the speed and precision of cleaning increase, and the cleanliness achieved after this process lasts longer. In addition, its use cannot cause damage to surfaces, and the need for human labor for cleaning a place is reduced.

Tips for Using Industrial Pressure Washers

It is better to observe some tips when working with an industrial pressure washer to protect both yourself and the machine from damage. For example, if you are introducing chemical detergents into the water tank, you should use protective clothing or personal protective equipment. Also, prevent the power cable of the device from getting wet. Below are other tips for using an industrial pressure washer:

Avoid direct contact with the water stream.

Maintain a proper distance from the body during operation.

Water spray can throw small objects into other areas, so be careful of yourself and those around you.

Do not use the pressure washer in confined spaces.

Never use the pressure of water to move objects.

Place the device on a smooth and stable surface before turning it on to prevent slipping.

Use soft water for cleaning surfaces.

Adhere to the standard ratio of water to detergent.